|

SHEET METAL PROCESSING WITH PRECISION

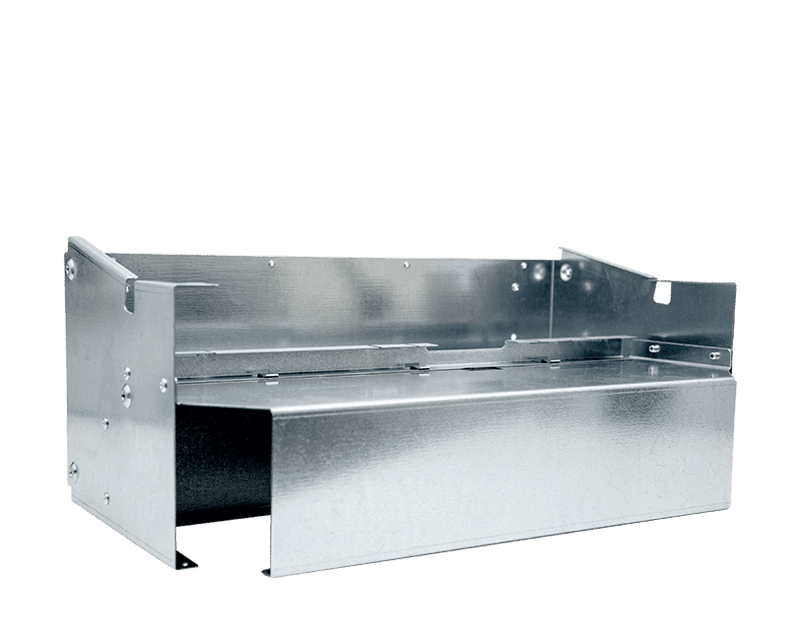

FROM BENDING TO MACHINING

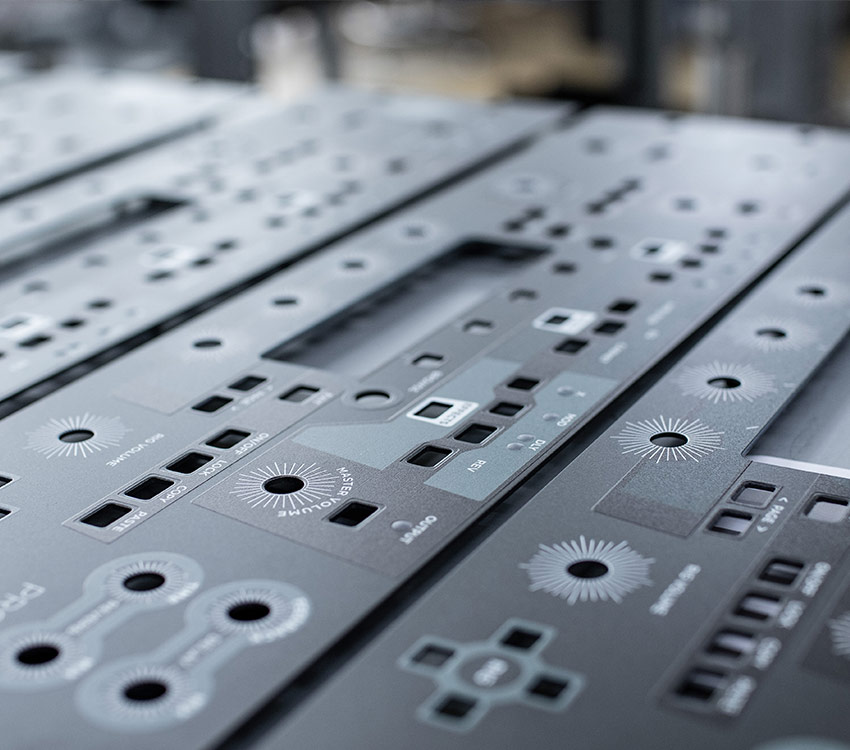

As a specialist for sheet metal processing, we work with a modern and high-tech machine park. The possibilities for processing sheet steel, stainless steel or aluminum are extremely versatile. We manufacture components with complex machining processes such as laser cutting, stamping and nibbling, forming and embossing. Thanks to state-of-the-art software (CAD-CAM), we are able to either use existing customer data for the production order or create the design according to your specifications.

Procedures for sheet metal processing

The processing, treatment and finishing of raw sheet metal through to finished products often requires numerous work steps. After programming, this includes precise cutting, shaping by edging and joining using welding technology. There are numerous individual procedures for processing sheet metal:

What we make out of sheet metal

Laser processing of all common materials up to 6 mm thickness

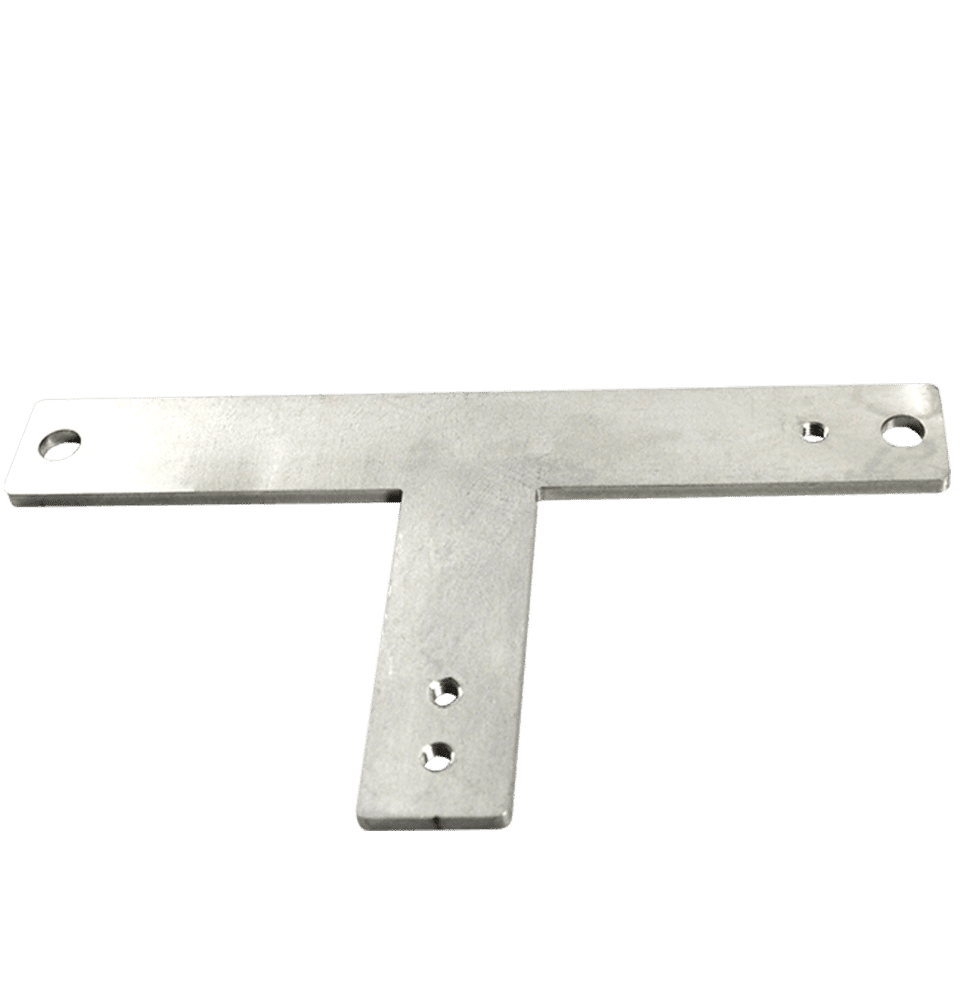

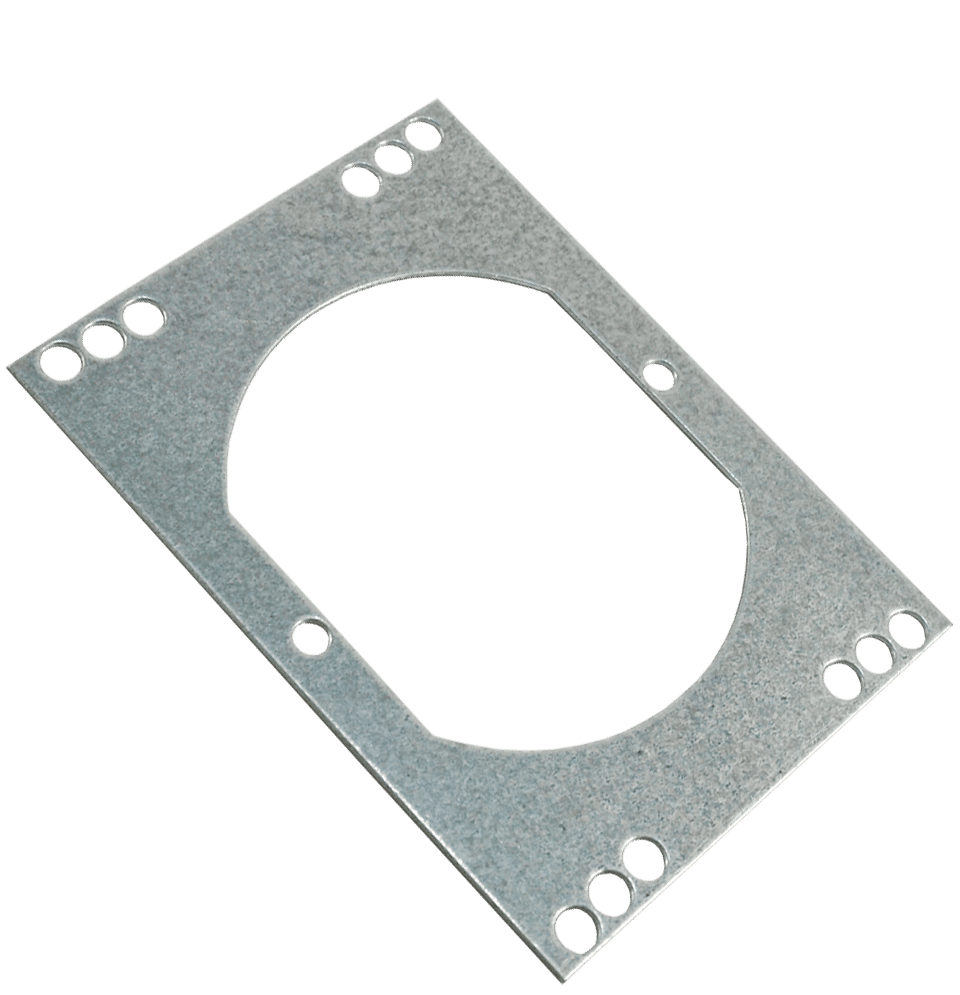

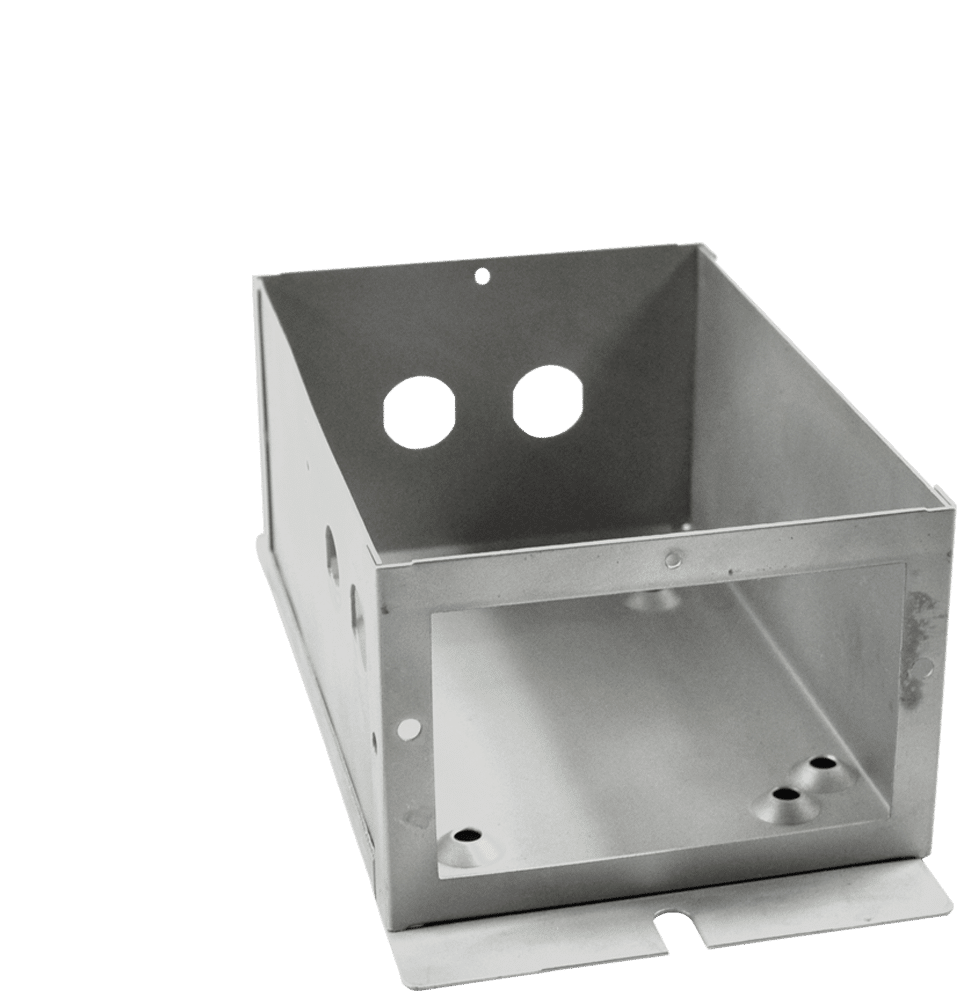

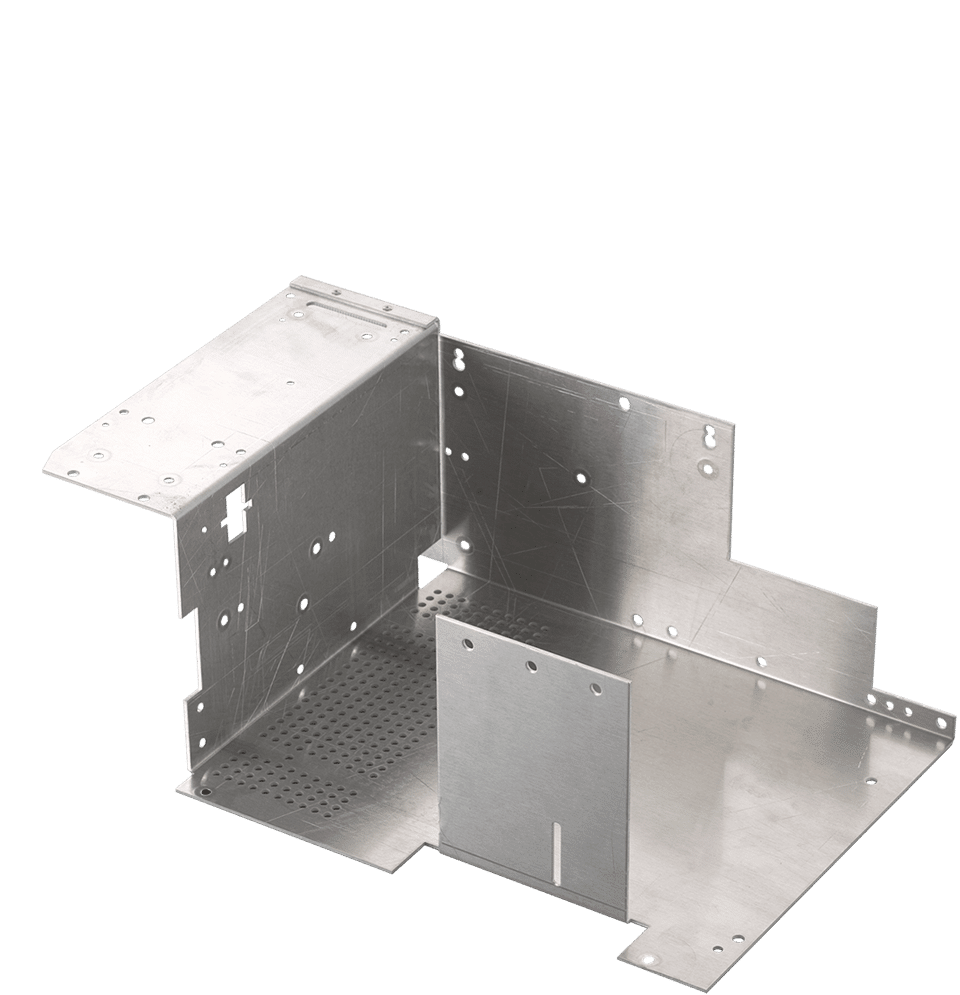

Components and parts made of sheet steel, stainless steel and aluminum up to a maximum sheet thickness of 3 mm

Milled contours, surface removal from aluminum and plastic

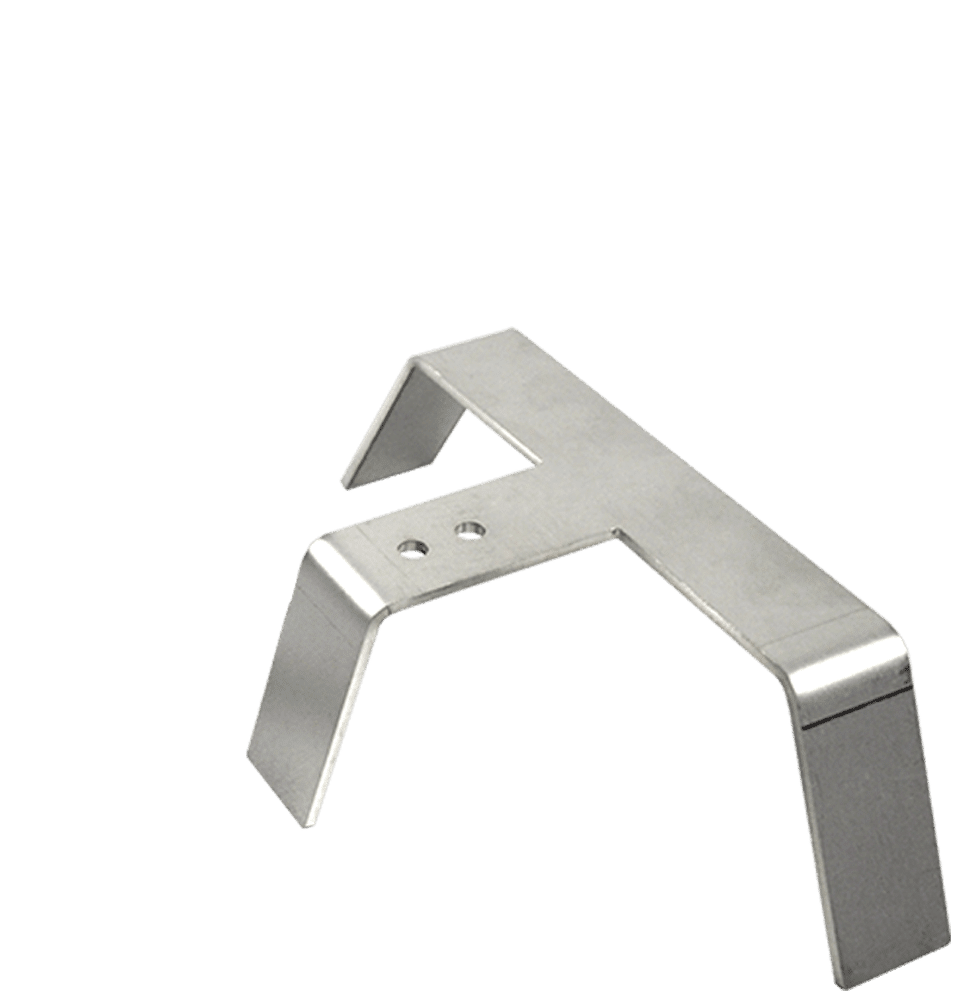

Precision bent parts and folded sheets up to 3 mm sheet thickness

Different sheet metal parts connected as an assembly using welding processes

.

Components with complex processing, such as lasering, punching, forming and embossing

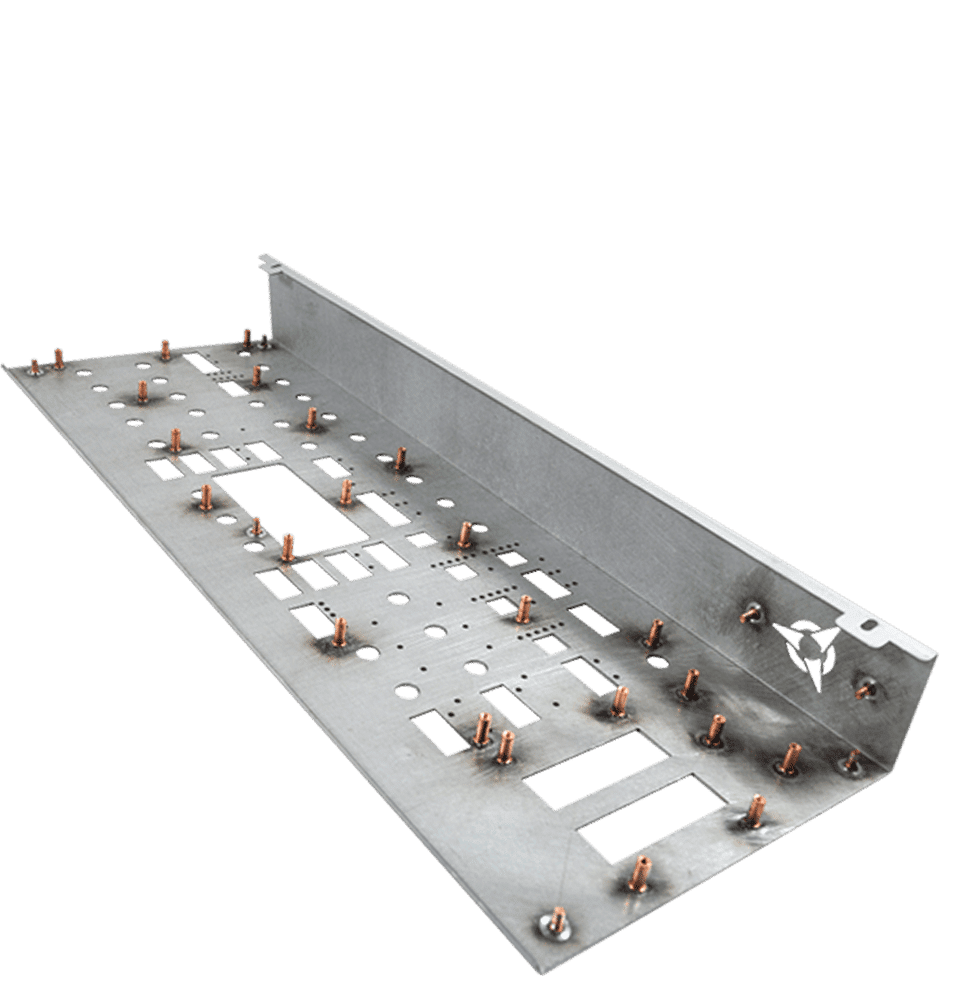

Bolt welding on sheet steel, stainless steel and aluminum up to 8 mm in diameter

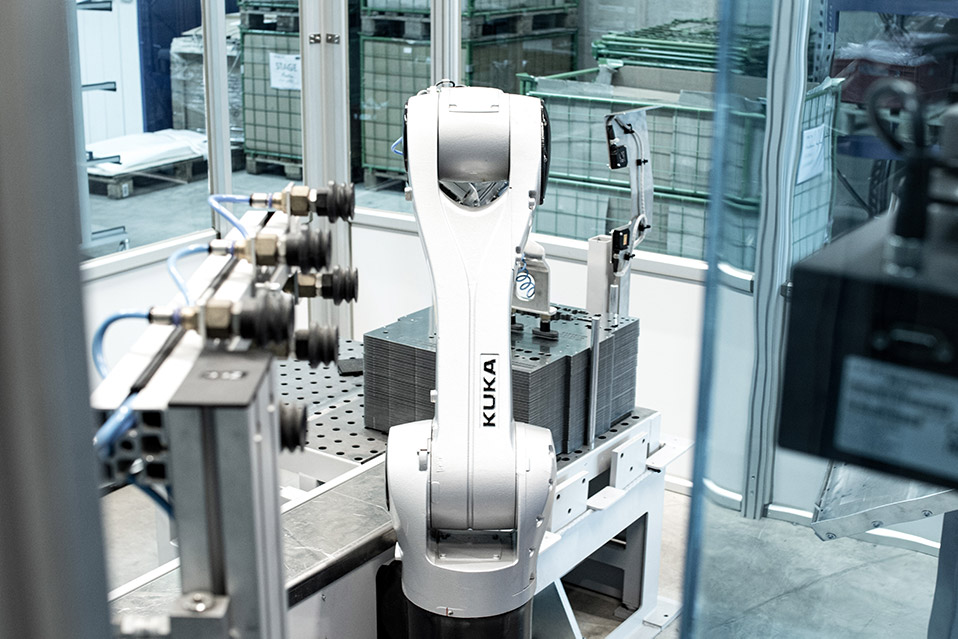

Fully or semi-automatic

press-fitting of bolts, corner connectors and special parts

We get your parts into perfect shape

Low production tolerances and efficient processes are a number of decisive advantages in sheet metal processing via the One-Stop-Shop. The raw sheet metal through to the finished component is in one hand. We carry out all processing steps through to the finished product “in-house”. You benefit from our experience, the expertise of our employees and our vertical integration.

The result is an economic advantage in the production of your sheet metal parts. In addition to the favorable production price in sheet metal processing, you receive dimensionally accurate and perfect components. Without any intermediate transportation, simply from a single source. From our location in Halsenbach in Hunsrück, between Koblenz and Simmern, we ship sheet metal parts and casings worldwide.

Fine sheet metal processing

according to your wishes

Thanks to state-of-the-art software (CAD-CAM), we are able to either adopt existing customer data for the production order or create the design according to your specifications. In the further course of our partnership, we are always available to provide advice and support when it comes to improving components and processes.

Batch sizes

Prototype or medium-sized series – you decide! We adapt individually to the requirements of your project. When creating prototypes, we are by your side and help to create the basis for series production of sheet metal and thin sheet metal parts as efficiently as possible. Our production capacities are geared towards small and medium-sized series.

Application of sheet metal parts

in various business areas

Whether complex assemblies or simple sheet metal blanks: assemblies and products made of sheet metal are used in many industries. Mainly in industrial applications. These include the following applications:

Your benefits at a glance

contact

As a full-service partner, we are always by your side. A fixed contact person, short distances and joint decisions.

price models

You benefit from attractive prices in the one-stop store for sheet metal parts – with experience and efficient production technologies.

quality

Quality is no coincidence. We manufacture with precision and always check every detail. We are also specialists in thin sheet metal.

Frequently asked questions about sheet metal

The mechanical processing of sheet metal into a specific shape.

In general, this is used to create individual sections, deformation by edging or bending or to create holes or threads in the material.

Essentially, this involves the production of products, components and parts from metal. A number of procedures have been developed for this purpose. A sheet metal part is created using various processing methods. The oldest process is forging and shearing. Over the years, this has been partially replaced by modern machining methods such as punching and nipple technology. The newer and innovative processes include laser cutting or water jet cutting.

Reshaping:

This includes rolling, drawing, edging and bending sheet metal

Sheet metal is a semi-finished product and can be formed in many ways. This also includes these processes:

Cutting and sharing:

Sheet metal cutting using sheet metal shears (manual), punching and nibbling, laser cutting technology or water jet cutting.

Machining and punching:

By milling, grinding, drilling, shear cutting, punching, laser cutting

Joining:

Sheet metal elements can be joined together by welding or screwing. Often necessary for constructions.

The tolerances are defined according to the requirements. In order to achieve the best possible cost-saving and high-quality result. For this purpose, the tolerances are in the small tenths to hundredths of a millimeter range, up to a thousandth for cut-to-size parts.