01

/ 03

Fine sheet metal

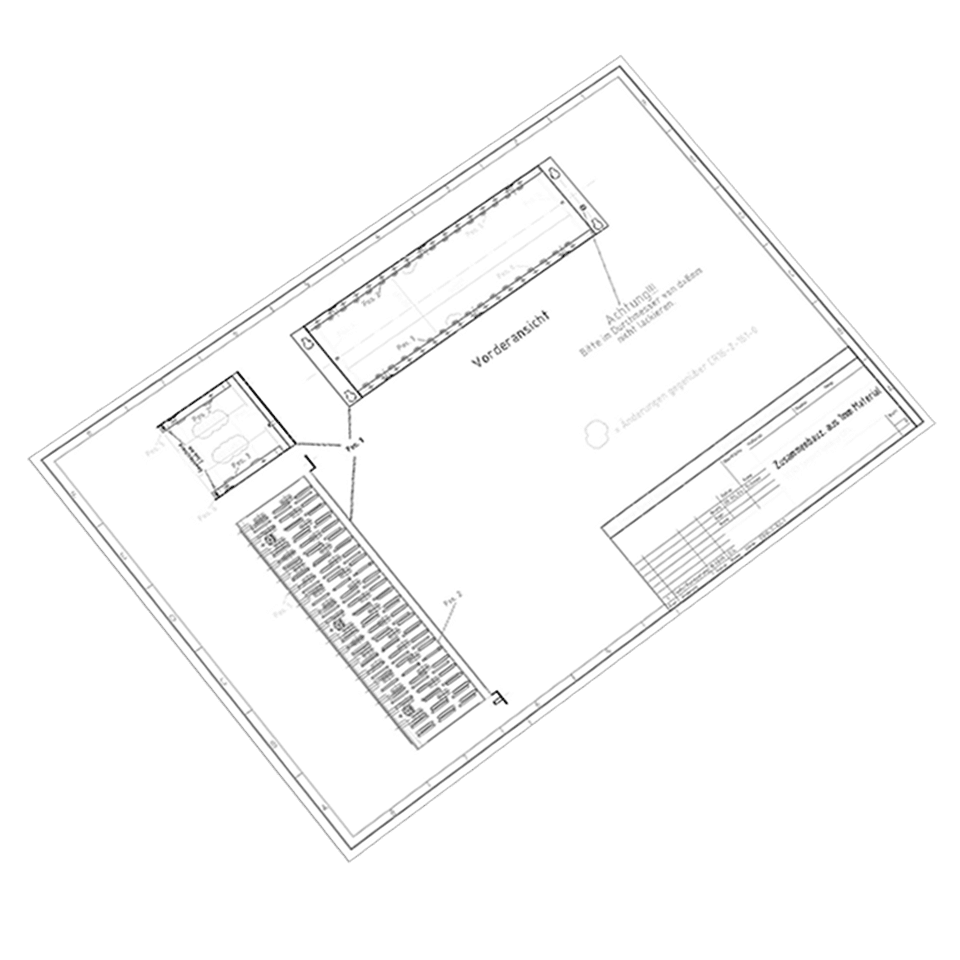

Laser cutting, punching, bending, cutting or welding – the core of our expertise is sheet metal processing.

Whether powder coating, wet paint, screen or UV printing – we ensure the perfect finish for your components.

On request, we can take over the complete installation of your components, including functional testing of the end devices.

Customized enclosure solutions made of sheet metal, including parts production, printing and design according to your wishes.

Welcome to HMT Rüffel, your system partner and professional service provider for sheet metal processing, housing and assembly production. We turn your individual ideas or exact specifications from drawings into metal. This applies in particular to small and medium-sized series.

We see ourselves as your system partner who can produce particularly economically and just on demand. What’s more, we look at the process chains together and develop optimization potential or quality advantages. We see your deadline and quality targets as our task. From simple sheet metal parts to complex chassis or housings.

You decide whether you want us to supply individual sheet metal parts, complete housings or finished products. In addition to mechanical assemblies, our range of services also includes the installation and testing of electronic assemblies. On request, our assembly service also includes functional testing and commissioning of devices, including packaging and shipping. On request, we can assemble, test, store and ship your products. Service from a single source in a cooperative partnership. Discover the possibilities of our vertical integration.

We work together to turn your idea into sheet metal and support you.

We check the components and planning. Development of the production process.

From raw sheet metal processing to plastic or wooden components, we do it all.

We assemble the entire assembly including the electronics and are at your side right through to dispatch.

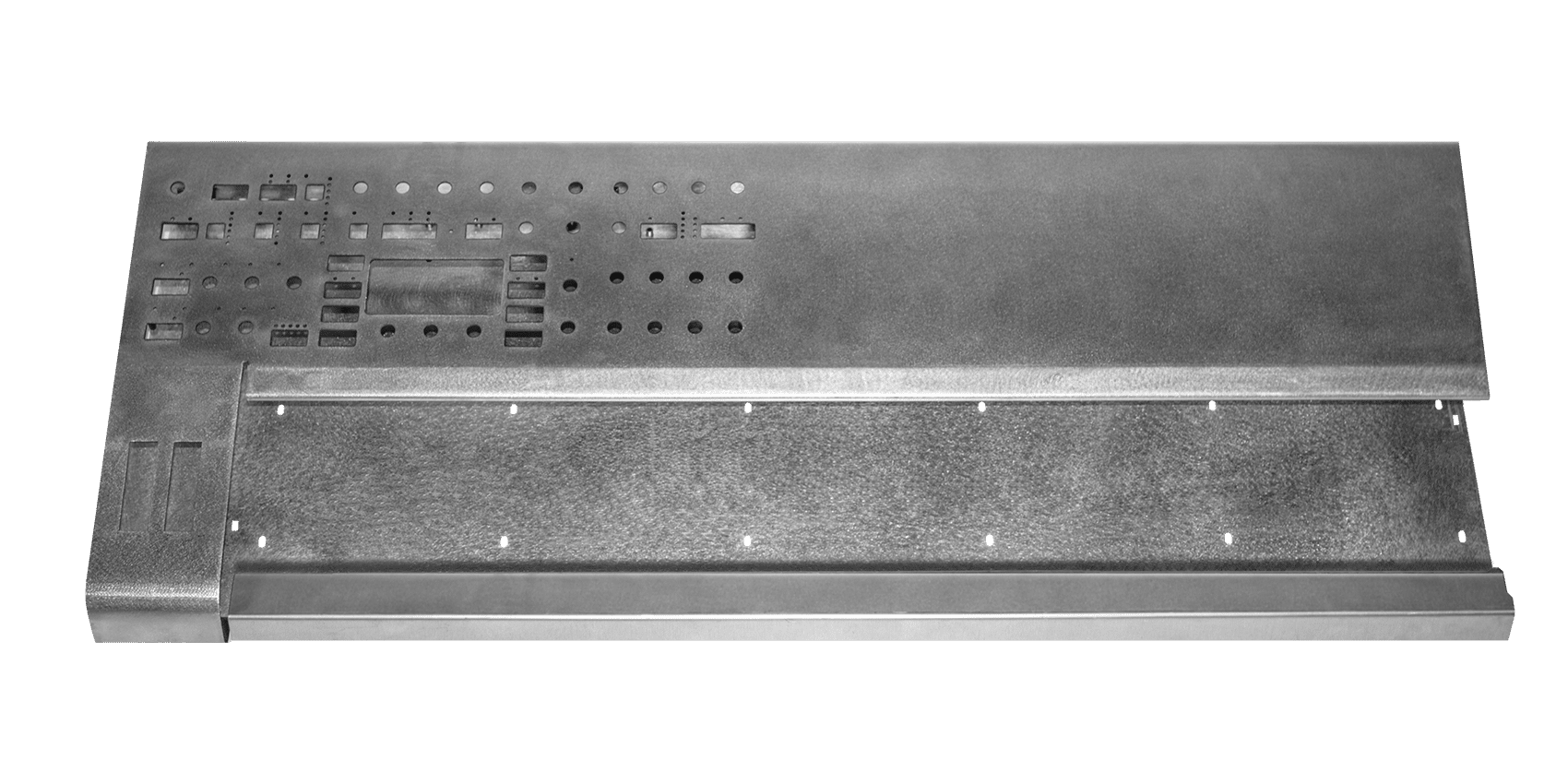

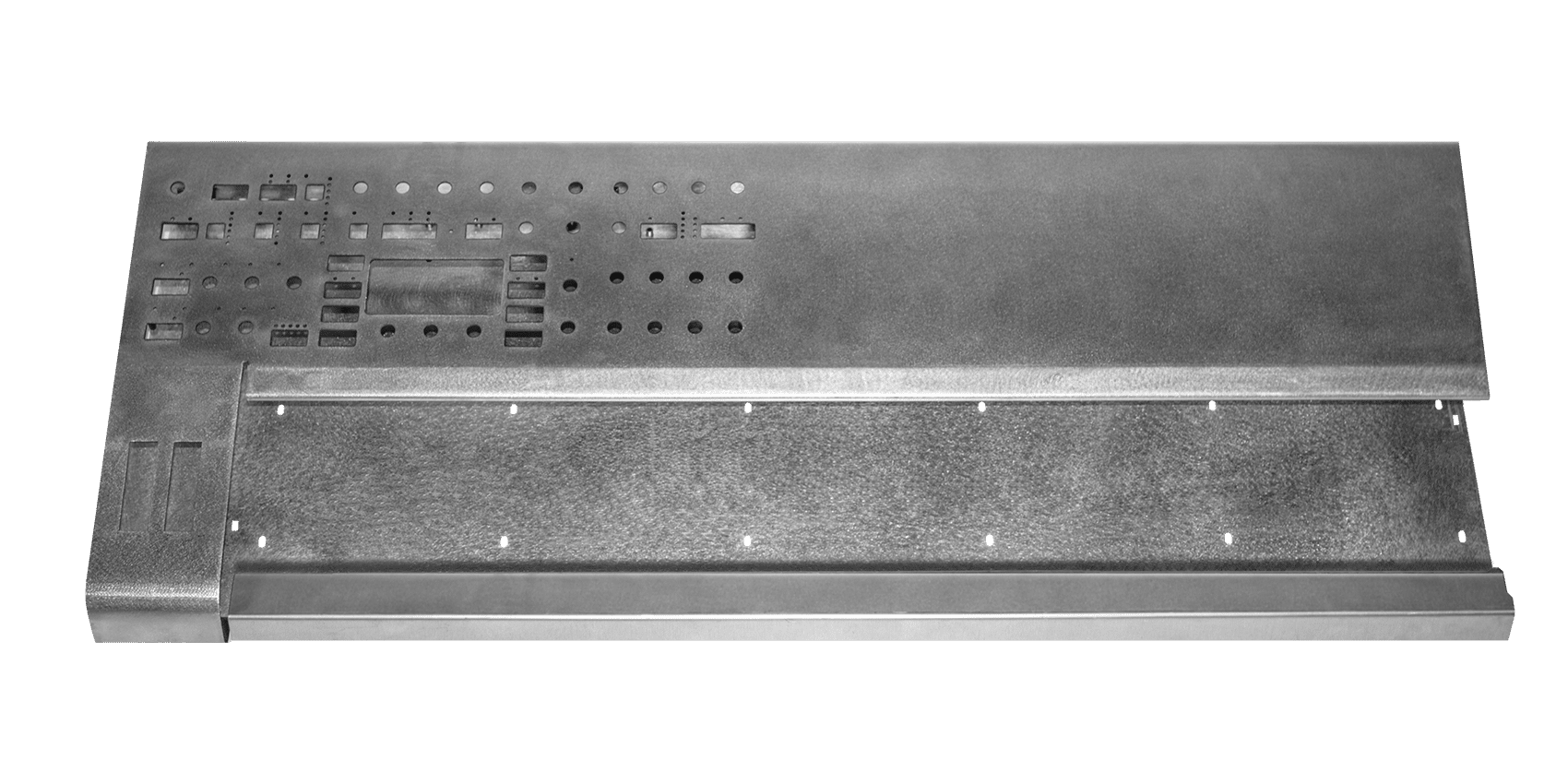

We have been a constant companion to the music industry for two decades. We work with start-ups, founders and leading manufacturers alike. This has resulted in a close partnership. Products are constantly being optimized. Ideas are developed in the joint design process. To the delight of the user and for a good sound experience. We manufacture:

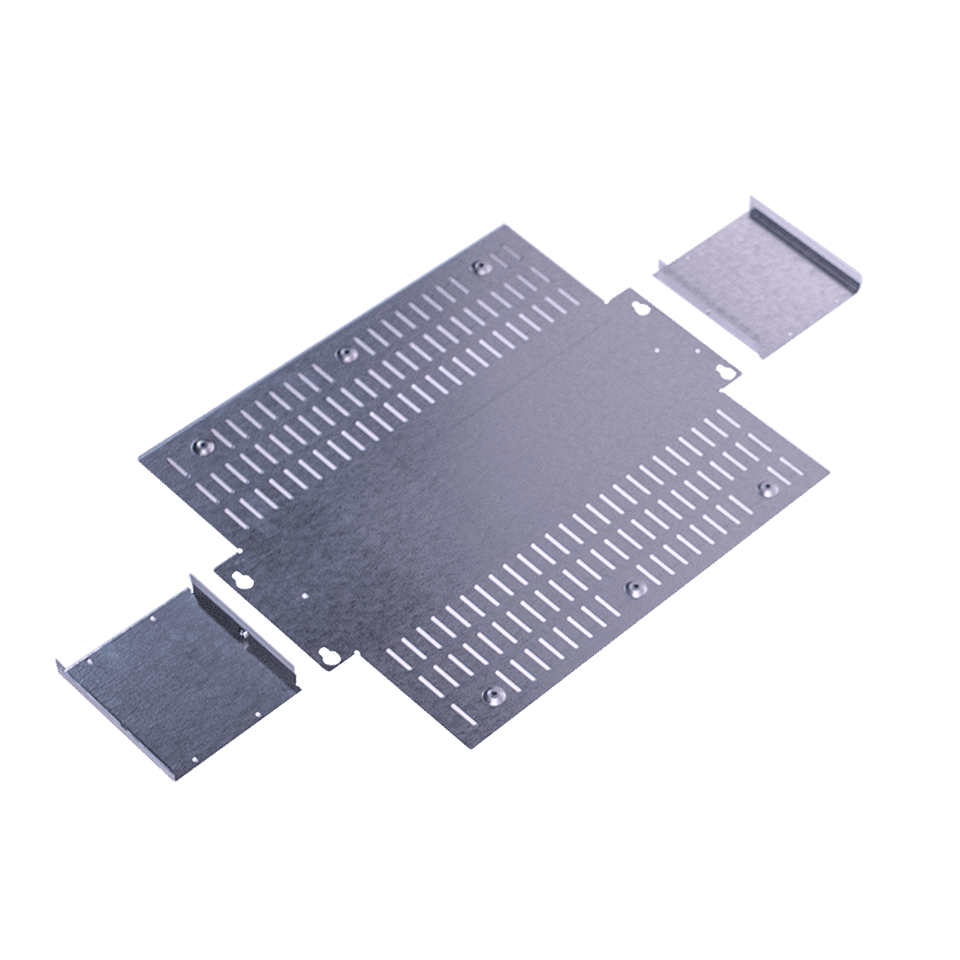

Innovation and cutting-edge technology are trademarks and state-of-the-art in medical technology. Complex slide-in housings for medical devices or entire assemblies are part of our portfolio. As an experienced service provider, we are always at the manufacturer's side. We manufacture according to specifications or in joint development:

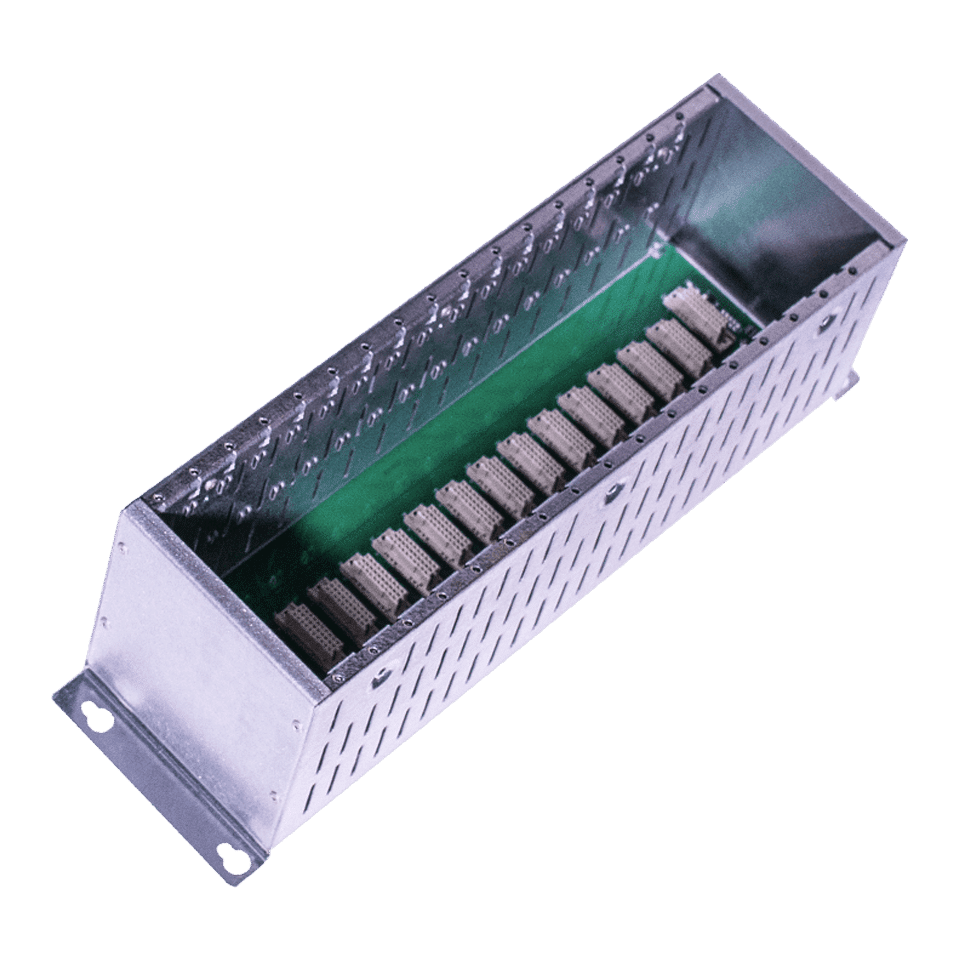

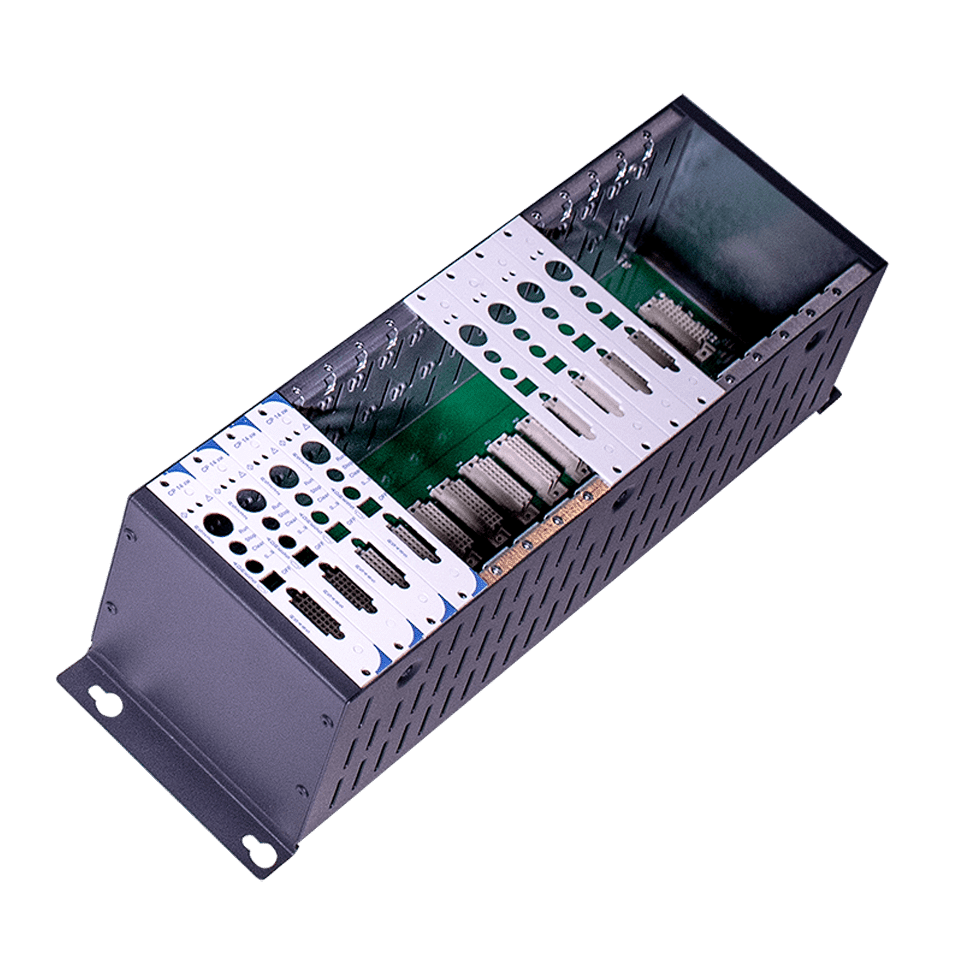

Whether a classic 19-inch rack, or enclosures for circuit boards or slots. Enclosure solutions are a key issue in the telecommunications industry. We offer production from a single source, including painting. Also including electronics assembly on request.