|

We know what surface processing is all about

The perfect finish for your sheet metal products

High-quality surfaces ensure the durability of components. They combine protection, design and functionality. We finish your sheet metal parts using innovative processes. The finishing of surfaces is complex and requires a great deal of expertise. Our services range from powder coating and painting to intricate UV or screen printing. There are virtually no limits to the design of a surface treatment. We realize your ideas and wishes in terms of color and shape.

PROCEDURES ALL AROUND THE SURFACE

No matter which surface finish is suitable for your product, we can do it for you. Whether powder coating or wet painting, whether screen or UV printing – with modern systems and our experienced specialists, we offer a wide range of specialized finishes.

WE PUT COLOR ON METAL WITH PRECISION

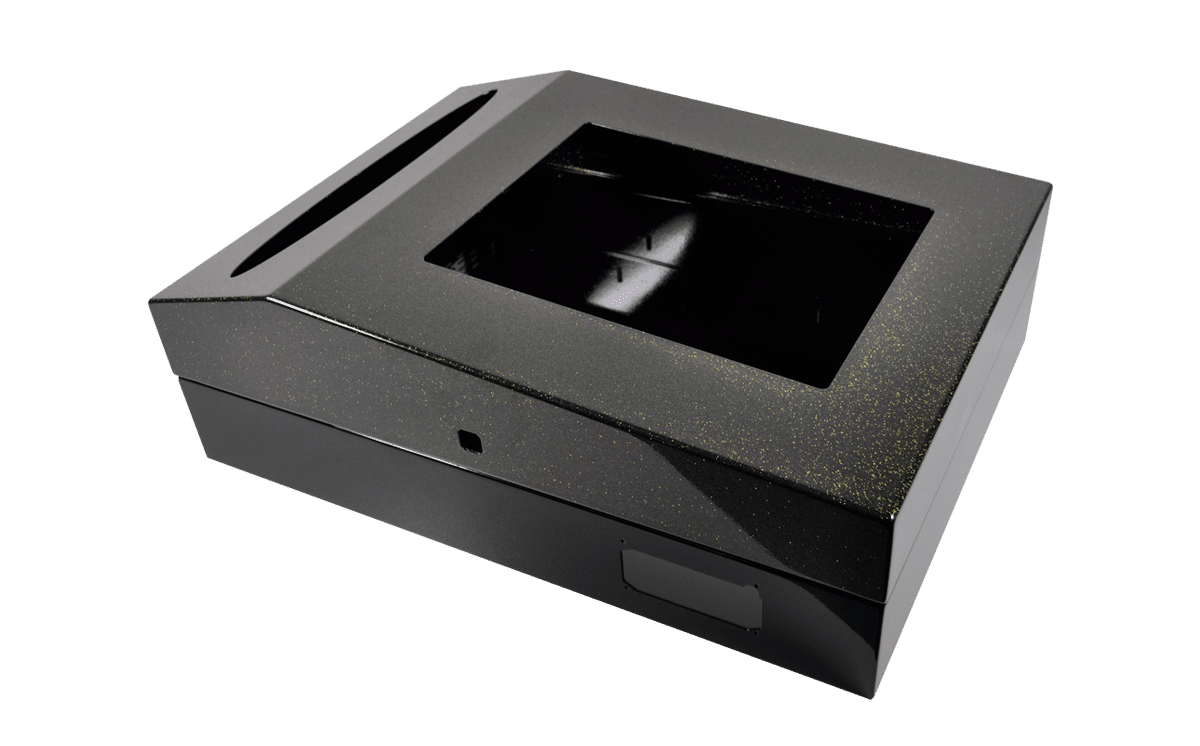

We paint and coat functional surfaces, from individual items to series production. We also produce decorative surfaces with high design standards in the color or surface effect you require. The component is in one hand from the raw sheet metal to the color finish. We can give your products a high-quality finish in all standard RAL colors. For special requirements, you can choose from an extensive range of special colors as well as metallic and effect paints.

THE RIGHT SURFACE FOR THE PURPOSE OF USE

In addition to color, shape and texture, a surface has to meet many other requirements. Ideally, all properties should be covered. A general distinction is made between

Corrosion-protective surface

Powder coating is ideally suited for this. Paint powder is electrostatically charged and sprayed onto steel or aluminum. This achieves a high level of corrosion resistance combined with a decorative appearance.

decorative finishing

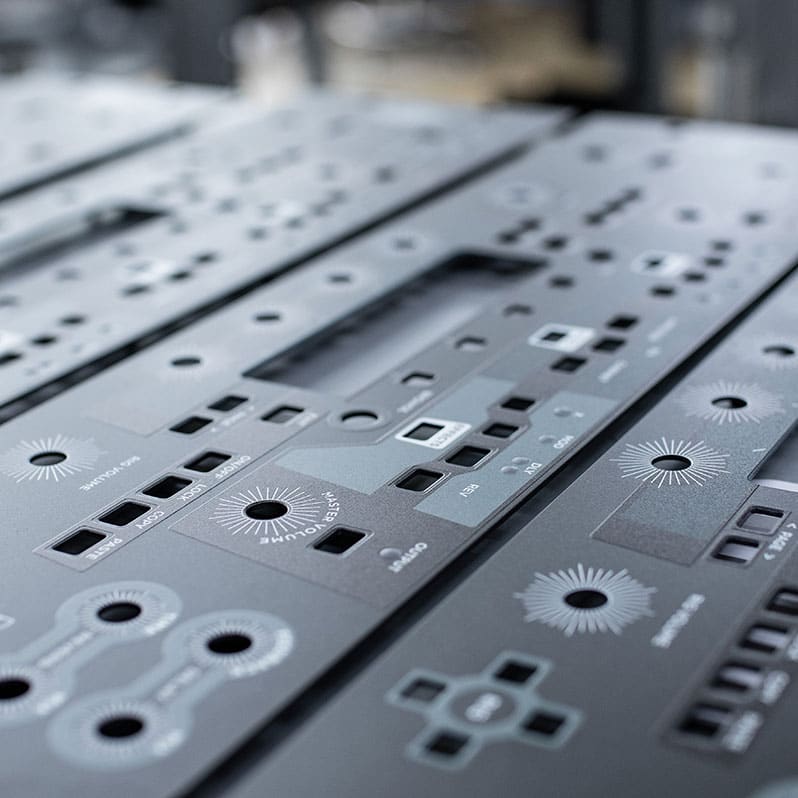

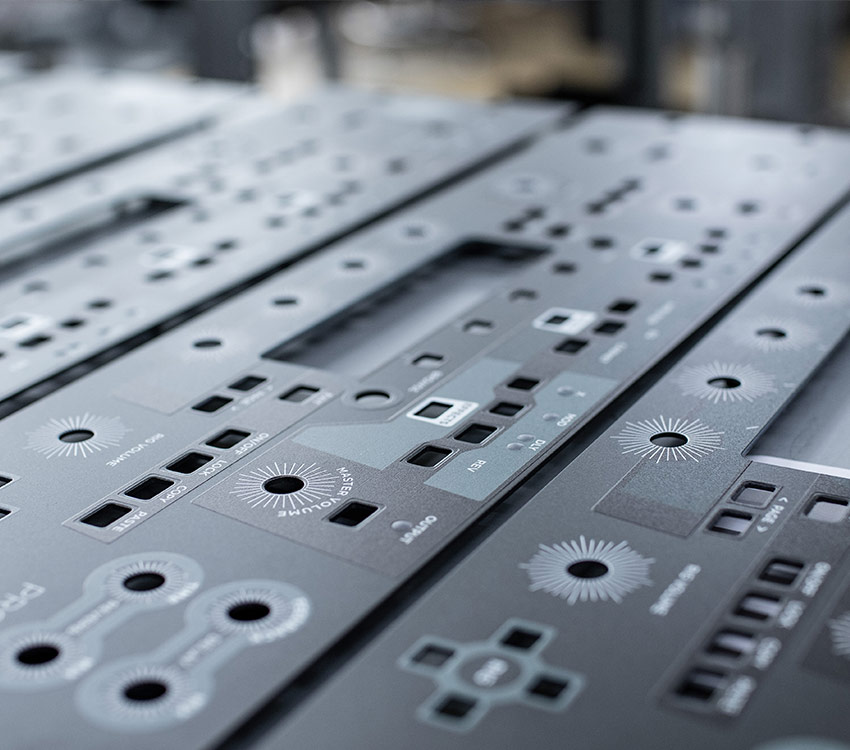

Primarily used for design products with very fine print elements such as letters or numbers or for complex print patterns. Decorative finishing offers the possibility of combining different finishing processes. For example, a painted sheet metal part can then be given a fine print pattern using precise UV printing. This is a common process in the production of front panels for the music industry.

FUNCTIONAL SURFACE

As a solution to give a surface a certain property. This includes, for example, a non-stick effect or protection against friction and wear. The use of certain additives during finishing makes it possible to optimize the coating in this respect. Alternatively, multi-layer applications can be used. This includes, for example, the application of clear lacquer or special impregnations.

Whether it’s a metal assembly, housing or front panel – as your partner, we create added value in surface finishing:

- We handle the entire production process, including finishing, from a single source

- Design surfaces, coatings and prints for all requirements

- High degree of individualization of your products

- Outstanding quality awareness and fair prices

- Support for your design process right from the start

By your side from the start

Finishing processes for metal surfaces include coating, lacquering and printing. The degree of individualization of your desired products is often determined by the design. We support you in the implementation of your ideas. From design to prototype, we are at your side. In this joint process, we develop the perfect finish. Guaranteed with a view to durability and functionality.

We adapt to your wishes. We create economic advantages even for small series. Our production is designed to be flexible. Individual surface finishing and surface coating stations are designed in such a way that variable production is possible. This means that all painted metal parts of an assembly find their way to final assembly on time.

- +49 (0) 6747 - 950184-0

- lack@rueffel.com

LINKS TO FURTHER INFORMATION

Your benefits at a glance

contact

As a full-service partner, we are always by your side. A fixed contact person, short distances and joint decisions.

price models

You benefit from attractive prices in surface finishing – with experience and efficient production technologies.

quality

Quality is no coincidence. We manufacture with precision and always check every detail. We are also specialists in thin sheet metal.